Ensuring patient comfort and preventing pressure injuries are paramount in modern healthcare. A specialized Medical Turning Mattress integrates advanced materials, ergonomic design, and automated functionality to redistribute pressure and facilitate safe patient repositioning. This comprehensive guide explores the essential aspects of these innovative support surfaces, emphasizing our product’s unique selling points. You’ll gain insights into the science of pressure redistribution, the cutting-edge materials that enhance durability and sustainability, customizable therapy options, clinical applications across care settings, contrast with conventional hospital mattresses, infection-control protocols, and economic considerations. By the end, healthcare professionals and facility managers will understand why investing in a premium Medical Turning Mattress translates to better patient outcomes, streamlined workflows, and long-term savings.

Understanding the Role of Medical Turning Mattress in Patient Care

Pressure injuries—commonly known as bedsores—affect millions of patients worldwide, leading to discomfort, infection, and increased healthcare costs. Traditional repositioning methods rely on manual turning by caregivers every two hours, which can be labor-intensive, inconsistent, and sometimes painful for patients. A Medical Turning Mattress automates or assists this process, using alternating pressure zones or lateral rotation mechanisms to shift the patient’s body weight gently.

By redistributing pressure points at regular intervals, these mattresses mitigate ischemia in vulnerable tissues. Clinical studies demonstrate up to a 60 % reduction in pressure ulcer incidence when utilizing turning mattresses compared to static foam surfaces. Beyond pressure relief, the gentle motion enhances circulation and respiratory function, reducing risks of atelectasis and pneumonia. In post-operative and critical care environments, the ability to modulate turning frequency and amplitude supports individualized therapy protocols, aligning with each patient’s risk profile and tolerance.

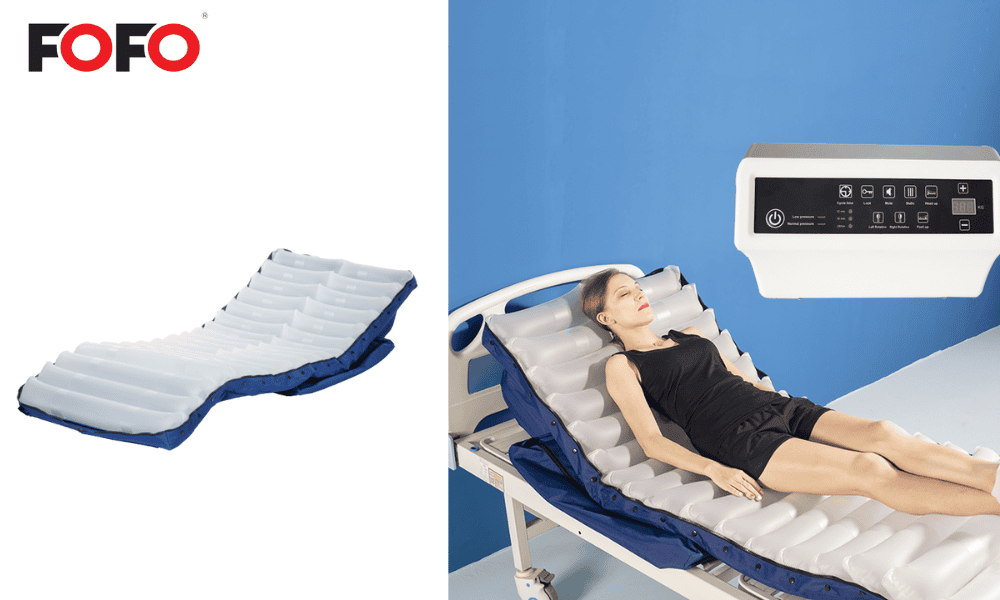

Our Medical Turning Mattress features programmable turning cycles—from gentle lateral tilts of 10° to full 30° rotations—ensuring optimal pressure redistribution based on body mass index, comorbidity status, and wound-care objectives. Care teams can customize settings via an intuitive touchscreen interface, integrating seamlessly with electronic health record (EHR) systems for automated documentation of turning events. This precision not only enhances patient safety but also frees nursing staff to focus on other care tasks.

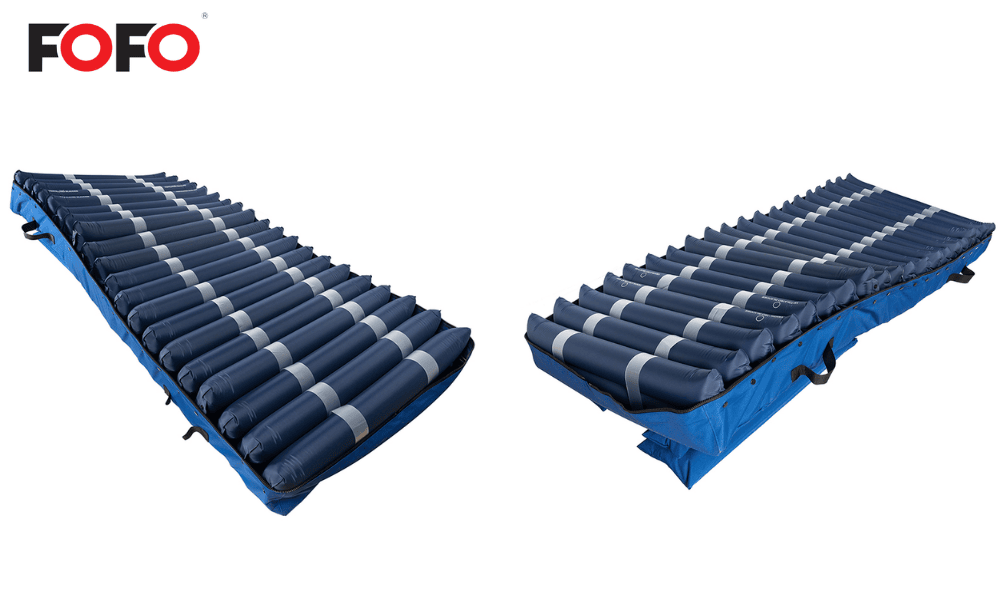

Medical Turning Mattress

Innovative Construction and Materials in Medical Turning Mattress

At the heart of any high-performance Medical Turning Mattress lies its materials science. Our product employs a multi-layer design combining a viscoelastic foam base, zoned pressure redistribution bladder arrays, and a high-frequency welded cover that resists fluid ingress and microbial growth.

The viscoelastic foam—engineered with open-cell architecture—conforms to body contours, providing baseline comfort and reducing shear forces during turning. Embedded within are custom polyurethane air bladders arranged in overlapping zones. During a turning cycle, alternating inflation and deflation of these bladders gradually tilt the patient up to 30°, then return to neutral posture, all without sudden movements that could exacerbate pain or dislodge medical devices.

Cover materials are equally critical. Our laminated nylon-polyurethane fabric is PVC-free, latex-free, and features an antimicrobial coating that inhibits bacterial colonization. Sealed seams created via high-frequency welding ensure no fluid penetration, safeguarding internal mattress components from contamination. This robust construction extends the mattress’s service life—to over five years under heavy use—while facilitating thorough cleaning and disinfection between patients.

Furthermore, the entire mattress assembly passes international medical device standards (ISO 14971 risk management, IEC 60601 electrical safety) and is certificated under FDA’s Class II medical device regulations. These certifications guarantee reliability in demanding hospital and long-term care settings.

Ergonomic Adjustability and Pressure Distribution Features

A truly effective Medical Turning Mattress must accommodate a wide spectrum of patients—from lightweight geriatric individuals to bariatric cases exceeding 250 kg. Our system offers dynamic pressure adjustments, allowing clinicians to set optimal inflation pressures based on patient weight and sensitivity. Integrated pressure sensors continuously monitor interface pressures at key anatomical landmarks; if pressures exceed safe thresholds, the system automatically triggers emergency deflation cycles.

Ergonomics extend beyond turning. The mattress’s lateral rotation function—also called low-air-loss turning—combines gentle tilt with continuous airflow across the surface to reduce moisture accumulation and maintain skin microclimate. Patients who cannot self-adjust benefit from this passive therapy, experiencing less friction and shear, which are major contributors to pressure ulcer development.

Customizable therapy modes include static, alternating, and lateral rotation, all accessible via the central control unit. Care plans can specify cycle duration, rest periods, and maximum tilt angles. For instance, an acute-care patient with deep tissue injury may require frequent low-angle tilts, whereas a stable long-term care resident could use longer rest periods with less frequent turns. This versatility sets our Medical Turning Mattress apart, promoting personalized care pathways.

Clinical Applications: From Intensive Care to Home Healthcare

The adaptability of a Medical Turning Mattress makes it invaluable across diverse healthcare environments:

-

Intensive Care Units (ICU): Critical patients often cannot reposition themselves. Automated turning supports pulmonary hygiene and pressure management, reducing ventilator-associated complications.

-

Long-Term Care Facilities: Nursing homes face high pressure-injury rates. Implementing turning mattresses can lead to significant reductions in wound treatment costs and length of stay.

-

Rehabilitation Centers: Post-stroke or spinal cord injury patients benefit from gradual, controlled movements that prevent orthostatic hypotension and facilitate early mobilization.

-

Palliative and Hospice Care: Comfort and dignity are paramount. Gentle turning cycles minimize pain and enhance comfort during end-of-life care.

-

Home Healthcare: Portable versions of our mattress system, with lightweight pump units and compact designs, empower family caregivers to deliver clinical-grade turning therapy at home, avoiding frequent hospital readmissions.

Real-world case studies illustrate transformative impacts: a rehabilitation hospital reported a 45 % drop in pressure ulcer prevalence after deploying turning mattresses in its SCI (spinal cord injury) unit. A home-care agency noted higher patient satisfaction and fewer emergency transfers when homebound elderly received automated turning interventions.

Comparing Medical Turning Mattress with Standard Hospital Mattresses

Not all support surfaces are created equal. Standard foam or spring mattresses provide basic comfort but lack active pressure redistribution. Even advanced foam overlays, while inexpensive, require manual repositioning and cannot adapt to real-time pressure changes.

Alternating pressure mattresses offer intermittent inflation cycles but often lack controlled tilt functions, limiting their ability to emulate subtle patient movements. Low-air-loss surfaces maintain skin microclimate but do not reposition patients laterally. Our Medical Turning Mattress is a hybrid solution, combining active lateral rotation with low-air-loss ventilation, addressing both pressure redistribution and moisture management in a single device.

Cost considerations often deter facilities from upgrading. However, a lifecycle cost analysis reveals that preventing a single stage III or IV pressure injury (which can incur tens of thousands of dollars in treatment) offsets the investment in turning mattresses across multiple beds. Moreover, integrating therapy documentation into EHRs improves compliance with care protocols, avoiding regulatory penalties and enhancing reimbursement under value-based care models.

Sustainability and Eco-Friendly Materials in Mattress Fabrication

Healthcare sustainability is emerging as a key priority. Disposable overlays and covers generate significant waste. Our Best Turning Mattress adoption of durable, recyclable materials reduces environmental impact over its multi-year lifespan.

Key green features include:

-

Recyclable Foam Cores: At end-of-life, foam layers can be reclaimed and repurposed into non-medical insulation products.

-

Biocide-Free Antimicrobial Treatment: We use silver-ion coatings without harsh chemicals, balancing efficacy with environmental safety.

-

Energy-Efficient Pump Units: Our control modules incorporate variable-speed compressors drawing up to 30 % less power than legacy designs, reducing carbon footprints.

-

Modular Component Replacement: Instead of disposing of entire mattresses, wear-prone parts (e.g., bladder arrays, covers) can be replaced individually, minimizing resource waste.

By choosing a sustainable Medical Turning Mattress, healthcare providers demonstrate environmental stewardship and prepare for increasingly stringent green procurement policies.

Cleaning Protocols and Infection Control for Medical Turning Mattress

Infection prevention is non-negotiable in patient care. A robust cleaning regimen ensures that turning mechanisms and surface covers do not harbor pathogens. Our mattress features removes easily and withstands hospital-grade disinfectants (e.g., quaternary ammonium compounds, hydrogen peroxide vapor). High-frequency welded seams eliminate needle holes where fluids might accumulate, and the low-permeability cover resists bodily fluid penetration.

Recommended cleaning steps:

-

Remove cover and disinfect pump unit surfaces with EPA-registered disinfectants.

-

Wipe mattress surface thoroughly, paying special attention to seams and valve areas.

-

Allow complete drying before reassembly to prevent mold growth.

-

Conduct weekly microbial swab tests in high-acuity units to verify sanitation efficacy.

Training materials, including on-screen tutorials and color-coded maintenance schedules, accompany each mattress set, empowering staff to maintain compliance with Joint Commission standards and local infection control regulations.

Cost-Effectiveness and Long-Term Economic Advantages

While the upfront cost of a Medical Turning Mattress exceeds that of static foam, the return on investment is compelling. Preventing pressure injuries not only reduces direct treatment expenses—such as debridement, antibiotics, and extended hospital stays—but also lowers indirect costs like litigation risk and reputational damage.

A conservative estimate: preventing just two stage III pressure ulcers per year can offset the capital cost of a turning mattress system deployed across ten beds. Additional savings accrue from:

-

Reduced Labor Costs: Automated turning lessens manual repositioning demands on nursing staff, freeing up time for clinical activities that generate revenue or improve care quality.

-

Improved Patient Throughput: Fewer complications lead to shorter average lengths of stay, allowing hospitals to admit more patients.

In today’s healthcare landscape, patient safety, clinical outcomes, and operational efficiency are more tightly interwoven than ever. A Medical Turning Mattress represents a strategic investment that delivers on all three fronts. From cutting-edge materials and eco-conscious manufacturing to programmable therapy modes, seamless integration with EHRs, and rigorous infection control, our product embodies the next generation of pressure-injury prevention technology. Whether you oversee an intensive care unit, manage long-term care operations, or coordinate in-home nursing services, adopting an advanced turning mattress system positions your organization at the forefront of patient-centered care, sustainability, and cost containment.

5″ Turning Mattress for Anti-Bedsore

The evolution of support surfaces has culminated in the Medical Turning Mattress, a device engineered to automate pressure redistribution and enhance patient outcomes. This comprehensive guide delves into the clinical imperative for turning therapy, detailing how irregular blood flow and prolonged immobility contribute to pressure injuries.

We unpack the sophisticated multi-layer construction—viscoelastic foam, zoned air bladders, and antimicrobial covers—highlighting our proprietary design that delivers customizable tilt angles, real-time pressure monitoring, and low-air-loss microclimate management. Comparative analyses illustrate superior performance over static foam and traditional alternating-pressure models, while case studies underscore measurable reductions in ulcer incidence across acute and long-term care settings.

Sustainability aspects, such as recyclable components and energy-efficient pump units, align with green healthcare initiatives. Detailed maintenance protocols ensure seamless infection control compliance, and economic evaluations demonstrate rapid return on investment through labor savings, fewer complications, and enhanced patient throughput.

Whether for ICU, rehabilitation, or home-health environments, this guide provides actionable insights into selecting, deploying, and maintaining a Medical Turning Mattress that elevates standard of care while optimizing operational and environmental metrics.For example: “Want to learn more about Medical Turning Mattress? Contact us now to get a quote!”

Post time: 4 月-23-2025