Welding seams light checking

The main purpose of weld illumination inspection is to find possible defects in the weld, such as cracks, slag inclusions, lack of fusion, and lack of penetration. These defects may affect the strength, sealing and durability of the weld, thus posing a threat to the overall performance and safety of the product.

Through weld illumination inspection, defects in the weld can be discovered and handled in a timely manner, ensuring that the product quality in key areas such as medical rehabilitation products meets relevant standards and requirements, and improving product reliability and safety.

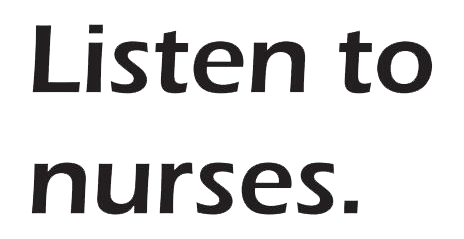

Dot size check

This inspection method is crucial in the production of medical rehabilitation products, because the accuracy of medical rehabilitation products is directly related to the patient's rehabilitation effect and safety. Through Dot size check, FOFO's QC team can promptly detect and correct dimensional deviations in the production process to ensure that the quality and performance of the final product meet the design requirements.

Regular inspection

By cutting one piece every 2 hours to check the welding line and conducting batch aging tests for more than 3 months, FOFO can control product quality more effectively and ensure the welding quality and long-term stability of the product. These measures help to improve the competitiveness of products and meet the rehabilitation needs of patients. At the same time, we continue to optimize the quality control process and improve the inspection efficiency to reduce production costs and improve production efficiency.

Cutting piece to check welding line every 2 hours

LOT aging test over 3 months

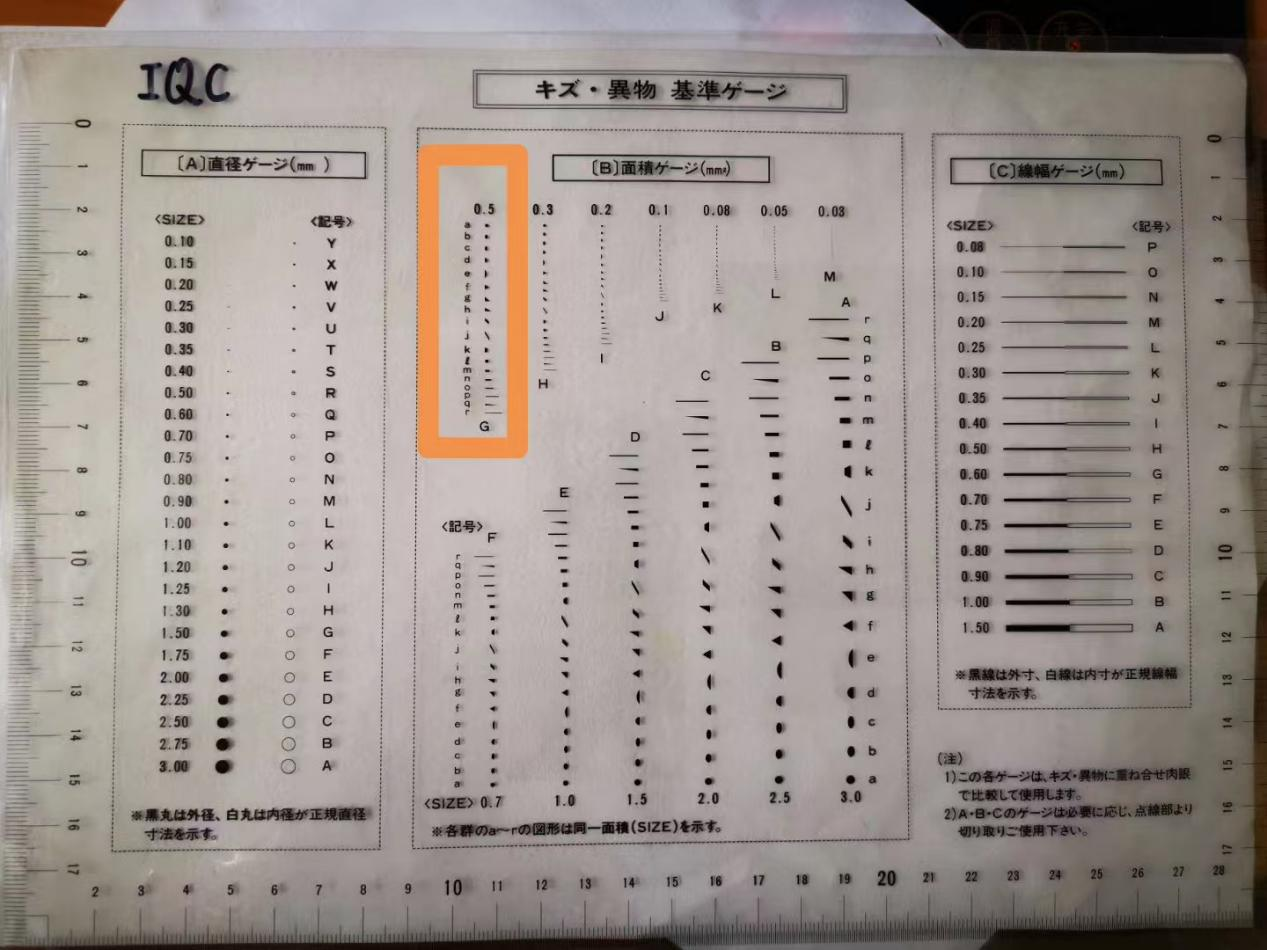

Product Quality Assurance

Loading mould test

Electric testing

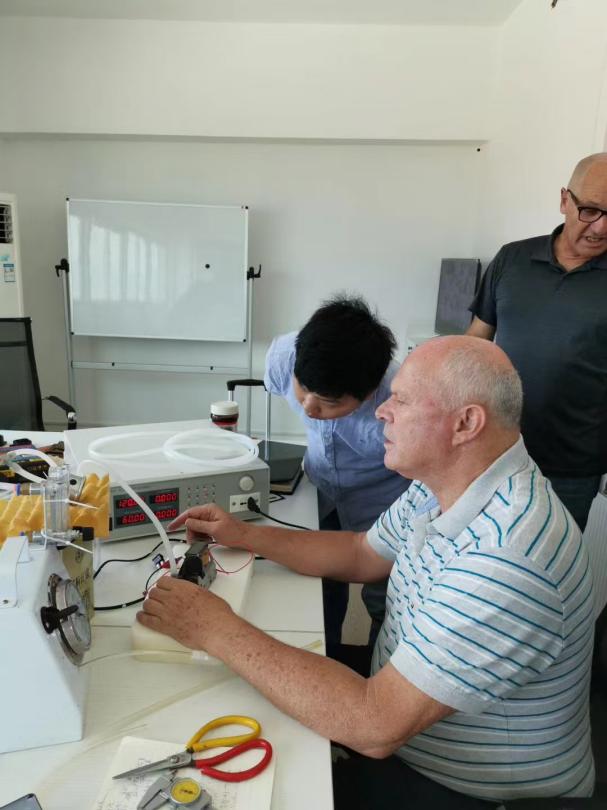

R&D & advancement

By jointly conducting performance tests on new designs with customers, FOFO is not only able to produce products that better meet market demand, but also to continue to learn and grow in the process of cooperation. In the future, we will further expand the depth and breadth of cooperation with customers in performance testing and jointly promote continuous innovation and improvement of products.

Mattress QC checking

100% air cells and mattress inflating test