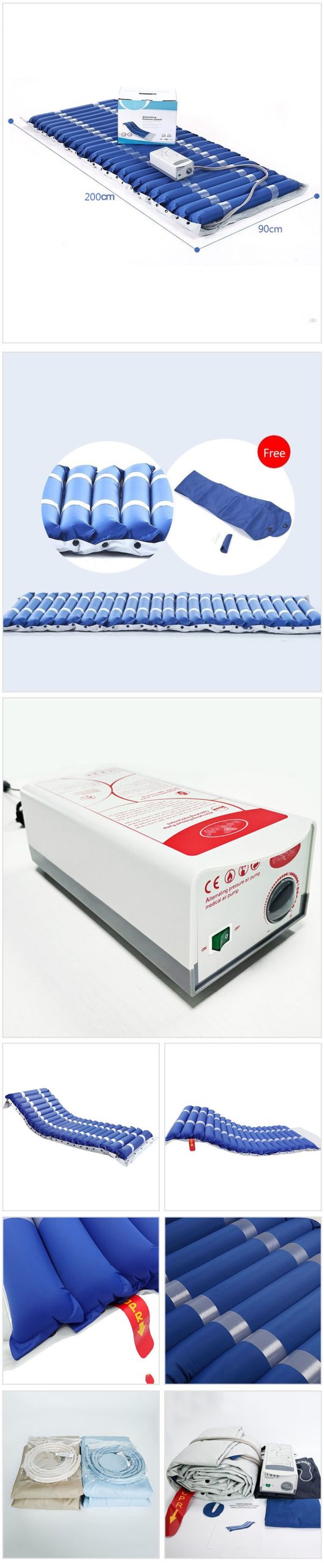

Tubular Nylon PVC Air Mattress For Hospital Or Home Use

Medical mattress material introduction

In the field of medical mattresses, it is crucial to choose the right material to ensure optimal comfort, support and hygiene for patients. PVC (polyvinyl chloride) and TPU (thermoplastic polyurethane) are two materials widely used in medical mattresses, each with unique properties and advantages.

PVC material:

Durability: PVC is a very durable material that can withstand long periods of use and frequent cleaning, making it ideal for the needs of hospitals and nursing facilities.

Waterproof performance: PVC has excellent waterproof performance, can prevent liquid penetration, keep the mattress dry, reduce the growth of bacteria and mold.

Easy to clean: PVC has a smooth surface and is easy to clean and disinfect, helping to maintain hygiene standards in the medical environment.

Cost effectiveness: The cost of PVC is relatively low compared to other materials, making it an affordable option.

Plastic: PVC has good plasticity and can be processed into various shapes and thicknesses to adapt to different medical mattress designs.

TPU material:

Elasticity and softness: TPU has excellent elasticity and softness, which is able to provide patients with a comfortable sleep experience while reducing the formation of pressure points.

Wear resistance: The wear resistance of TPU makes it ideal for medical mattresses that remain in good condition even under frequent use.

Temperature adaptability: TPU is able to maintain its performance over a wide temperature range and is suitable for use in different climatic conditions.

Biocompatibility: TPU has good biocompatibility, is non-irritating to human tissues, and is suitable for direct contact with the skin.

Recyclability: TPU is a recyclable material that helps reduce environmental impact and meets the requirements of sustainability.

Whether it is PVC or TPU, the choice of high-quality materials is crucial to the manufacture of medical mattresses. They not only affect the comfort of patients and the rehabilitation process, but also affect the operational efficiency of medical facilities and the health and safety of patients. By carefully selecting and combining these materials, mattress products can be created that both meet medical needs and provide an exceptional patient experience.

Product Description for Medical air mattress

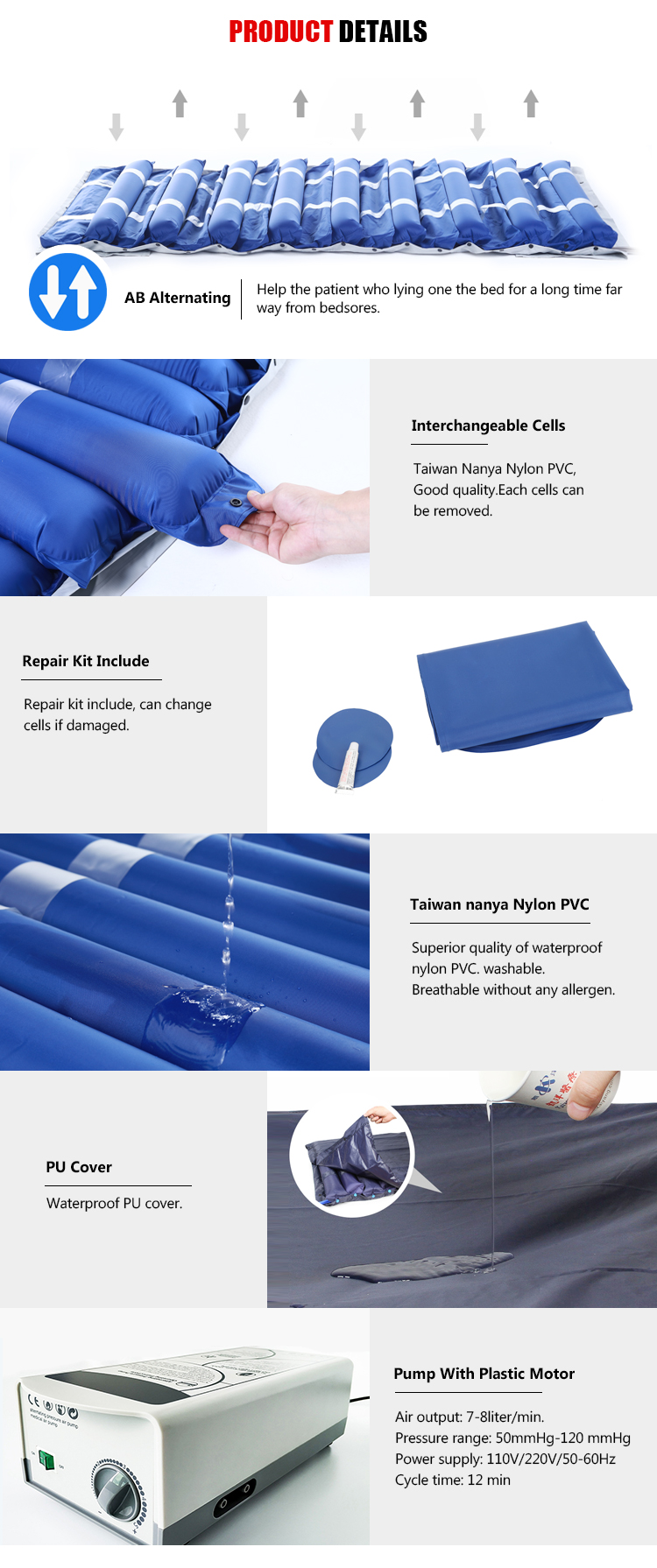

1. Our mattresses are mainly used for the patients who need to lie on bed for a long time, and keep them far away from bedsore or decubitus;

2. Use breathable material to keep skin dry and clean;

3. Frequent fluctuation massage;

4. Work quietly. Noise less than 20 decibels, with a comfortable sleep.

5. Offering a variety of wound care solutions for the treatment and healing of pressure ulcers.

It consists of durable shaped air tubes and control unit, can provide excellent pressure reduction through continuous alternating movement, which is designed in order to achieve good massage effect and blood circulation in body tissue and to help alleviate the pressure sore for patients on long-term medical treatment or for immobility.

On the other hand, our mattresses are heat sealed, so they are obviously durable.

Product Characteristics for Medical air mattress

1. Made of breathable materials, fire retardant, SGS approved;

2. Taiwan Nanya nylon PVC/ TPU material, breathable, washable and waterproof;

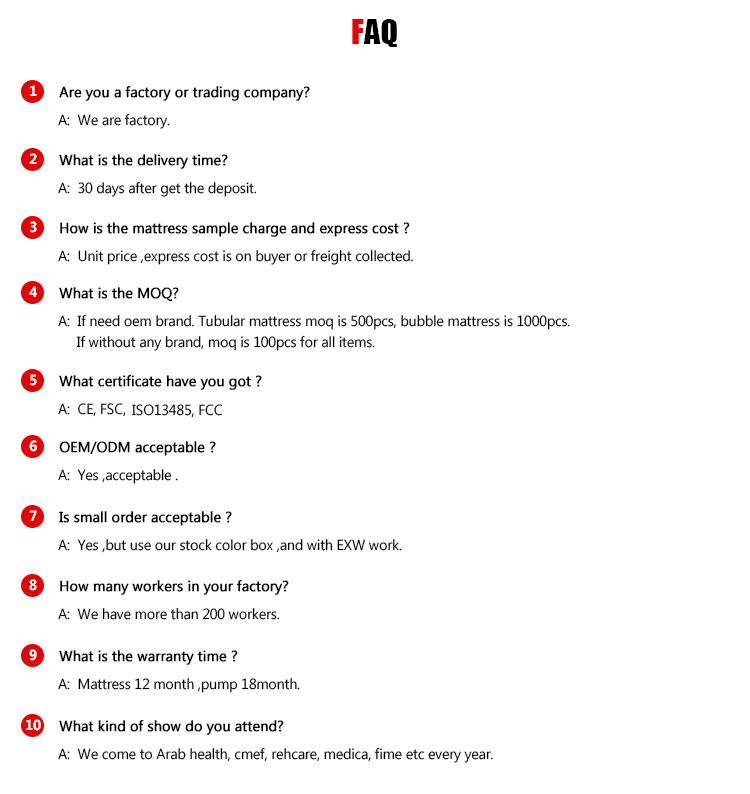

3. Individual cells, each one can be removed;

4. AB or ABC alternating optional;

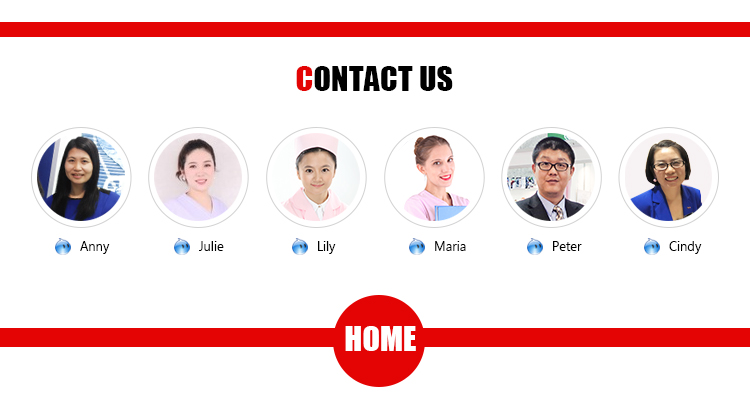

5. Low noise during operation;

6. Aluminum pump compressor’s excellent heat control makes it more durable, 2years warranty;

7. CPC connector included.

Data Sheet for Medical air mattress

HF6002 Series Mattress Specs for Medical air mattress